This DIY is sponsored by Home Depot. I'm so proud to be working with them on this content series where I'm reinventing old furniture and giving it a new life. I truly believe the best way to get higher quality furniture at a lower price point is to buy vintage pieces and repurpose them. Home Depot is dedicated to being eco-friendly and I think this type of recycling is a great step in the right direction. Thanks, Home Depot!

I really wanted a pair of tufted headboards for my girls rooms, but tufted pieces can be especially expensive! I picked up a pair of these vintage headboards for next to nothing at a thrift shop and thought I could probably come up with a way to reuse these rather than buying something new.

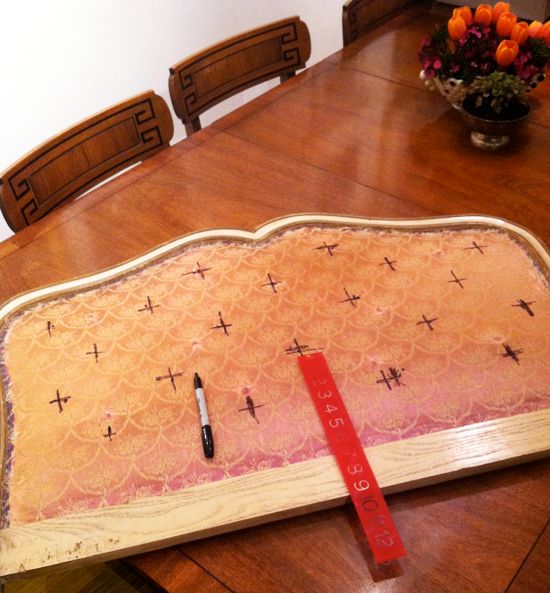

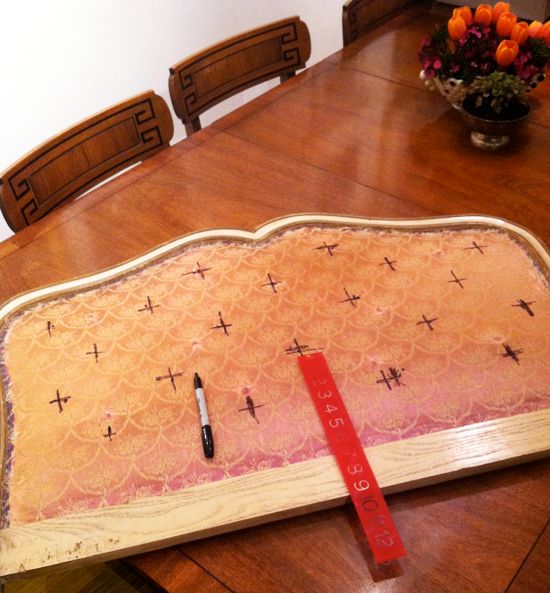

I took a quick photo and then played around in photoshop with the placement of the tufts. Since there are a lot of curves in this piece it wasn't just a matter of doing some math, like with most tufting projects I've done.

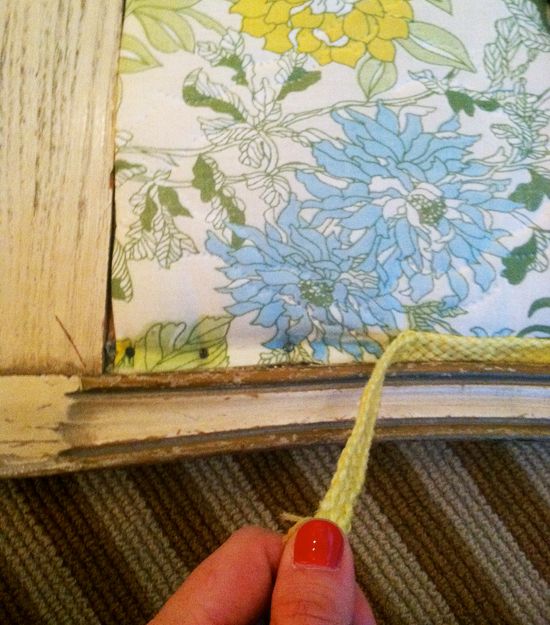

Once I had the tufting placement down, I started pulling off the old upholstery.

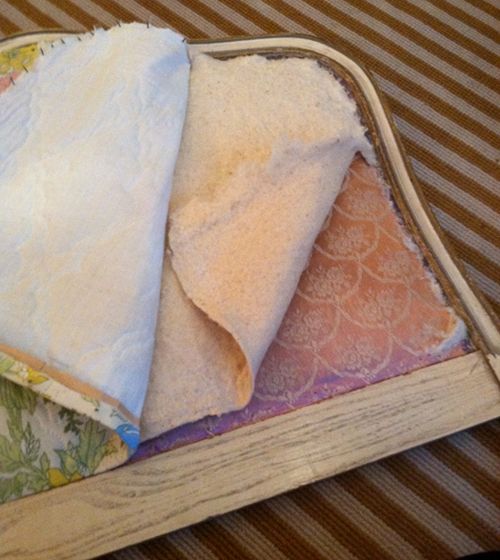

Underneath the top layer was a realllllly old piece of silk that was super sunbleached. I always love pulling apart old upholstery to see what fabrics are hiding.

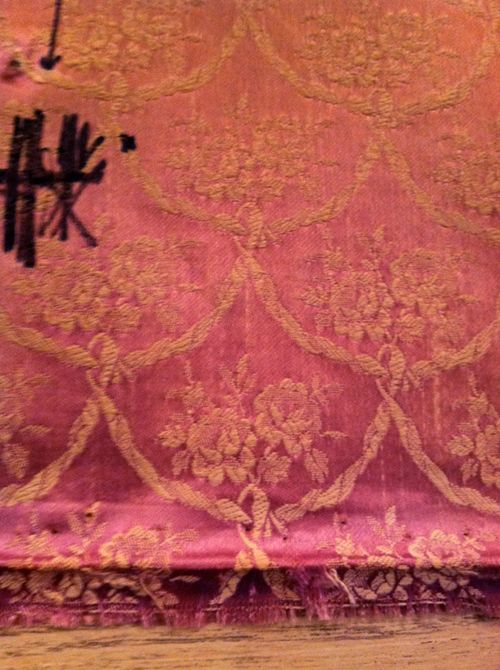

The part that hadn't bleached out was a gorgeous lilac. Played to my ombre obsession :)

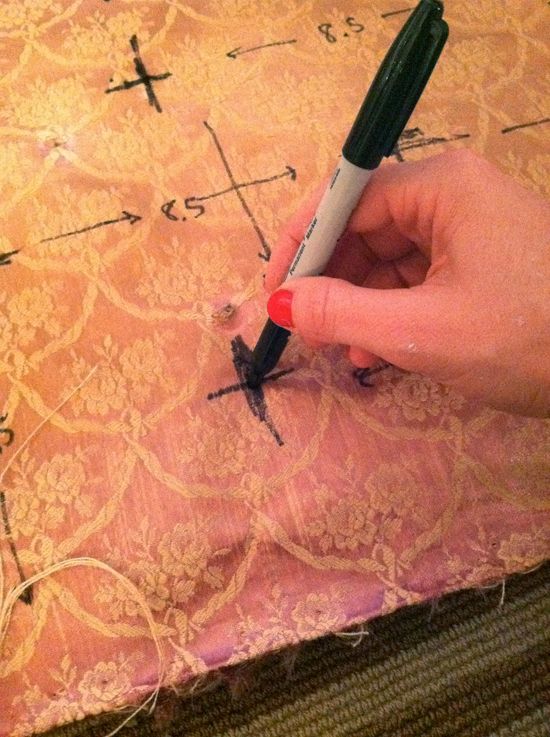

I used this underneath fabric to mark out my tufting design. The basic idea is to keep everything in straight rows and then offset the rows, like laying bricks or drawing polkadots. The rows will line up diagonally and horizontally.

Then I pulled off that bottom layer of fabric and batting so that all that was left was the wooden frame.

Then I pulled off that bottom layer of fabric and batting so that all that was left was the wooden frame.

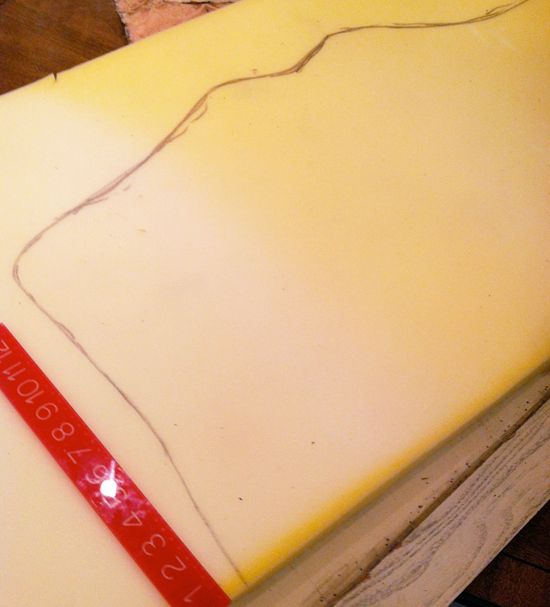

I used some of the batting to mark off the shape of my foam. I used the batting instead of the fabric because I needed to foam to be cut a little short so it would be pretty far inset from the bed frame.

The foam I used here was a repurpose too. I used some camping foam! It's such a cheap way to buy 2" or 3" foam.

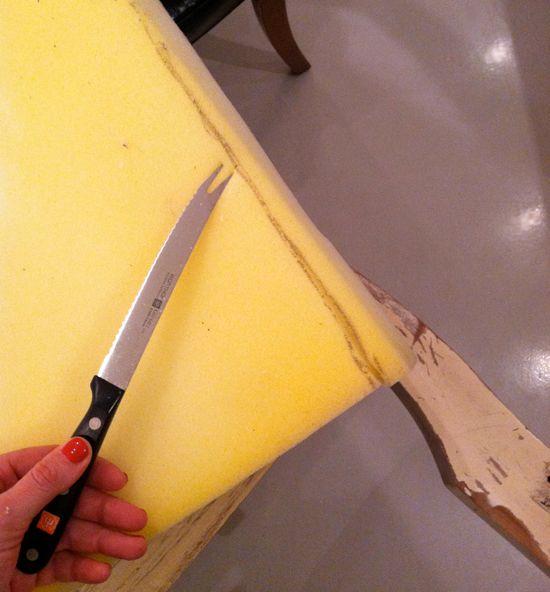

I used a serrated knife to cut out the shape, but I wish I had an electric knife. Those work so well for cutting foam.

The foam fit perfectly inside the frame, right where I wanted it, about an inch in.

I used a combination of the serrated knife and a pair of scissors to shave down the corners of the foam at about a 45 degree angle.

I cut some small holes in my fabric guide so I could draw some registration marks on the frame.

I had jotted down all the measurements on the fabric guide too, so it was easy to quickly double check my marks.

I drilled through the frame with a 1/4" drill bit. It's a good idea to drill pretty large holes in your frame backing to make the tufting go faster.

Once the holes were drilled, I layed the frame on top of the foam and marked the tuft placement by poking a sharpie through the drill holes.

The next step is vital to getting the deep-tuft look. You have to take out all the foam where each button will go. I just use a little paring knife to cut a simple hole around the registration mark. You want the hole to be sort of angled so the opening is wider and the bottom of the hole is about the size of your buttons.

One the foam is cut in an angled circle, you just have to grab the cut piece, pull, swirl and rip. This part goes so quickly!

You can cut or pick out addition foam as needed to created the right shape for the tufting holes.

I used my trusty can of spray glue to affix the back of the foam to the bed frame. You really want the foam to stay put during the tufting process so this step is important.

Cover the foam with a layer of high-loft batting.

Lay down your fabric on top of that and round up an extra long needle (mine's about 5") and some upholstery thread (Don't use regular thread here. It needs to be upholstery thread).

Turn on a show and enlist a cute little helper who is eager to push back bedtime.

I skipped explaining the step about making my own buttons because there are lots of different companies that make button covering kits and they all have different instructions. So just pick up a kit and some refill packs and follow the instructions on the back. I used 5/8" buttons here. Also I always use a little dollop of Magnatac glue when I make my own buttons, just to reinforce the hold, especially when using thick fabrics like velvet.

Okay so here's the tufting process:

1) Double up your upholstery thread and thread your long needle. I use two arm-lengths of thread each time and I can get two buttons done with that.

2) Your first tuft should be the middle hole in the very top row.

3) Your needle should pass first through the back hole, through the middle of your foam divot, and finally though your batting and fabric.

4) Leave about six inches of thread hanging in back and then thread your button in front. Because you doubled up your upholstery thread, four individual threads should be on your button.

5) Trying to keep all your threads tidy, pass the needle back through the foam and hole in the frame. It might take a few pokes to find the hole again since you're searching blindly, but it gets easier after a few tries.

6) Now pinch your button and sort of push and wiggle it down into the foam divot. At the same time, pull the threads from behind the frame.

1) Double up your upholstery thread and thread your long needle. I use two arm-lengths of thread each time and I can get two buttons done with that.

2) Your first tuft should be the middle hole in the very top row.

3) Your needle should pass first through the back hole, through the middle of your foam divot, and finally though your batting and fabric.

4) Leave about six inches of thread hanging in back and then thread your button in front. Because you doubled up your upholstery thread, four individual threads should be on your button.

5) Trying to keep all your threads tidy, pass the needle back through the foam and hole in the frame. It might take a few pokes to find the hole again since you're searching blindly, but it gets easier after a few tries.

6) Now pinch your button and sort of push and wiggle it down into the foam divot. At the same time, pull the threads from behind the frame.

{Next, get excited because that looks like a real, legit tuft. Also, send your little helpers to bed because it's after 8:00. Then enlist your sweet sister in law, who's in town visiting with her cute new husband, to lend a helping hand.}

7) With your helper pushing the button as far in as possible, pull the threads in back very tight and staple them down on to the frame. Pull the threads in the opposite direction and staple in again. Repeat a couple times and tap in the staples with a hammer to make sure the staples are flush and in there tight.

8) Here's the most important thing I can share with you here: Work in rows. Start with the middle button and work your way out in the row. Then start the next row in the middle again and work your way out.

Once you finish your first row and are ready to start the next row, play with your fabric and start making folds in a diamond shape. It's surprising how easily the fabric naturally folds into the diamond shape. The goal is for the surface of the upholstery to be smooth and as tight as possible. For a professional look, you want all the extra fabric to go in the folds.

Rather that placing your tuft wherever your needle appears and having to deal with the consequences with the folds later, CHOOSE where your button will go by making the folds first and sort of pushing your fingers in the foam divot. You'll know exactly where to put that needle and the button.

Keep working away, going row by row, starting from the center and working out.

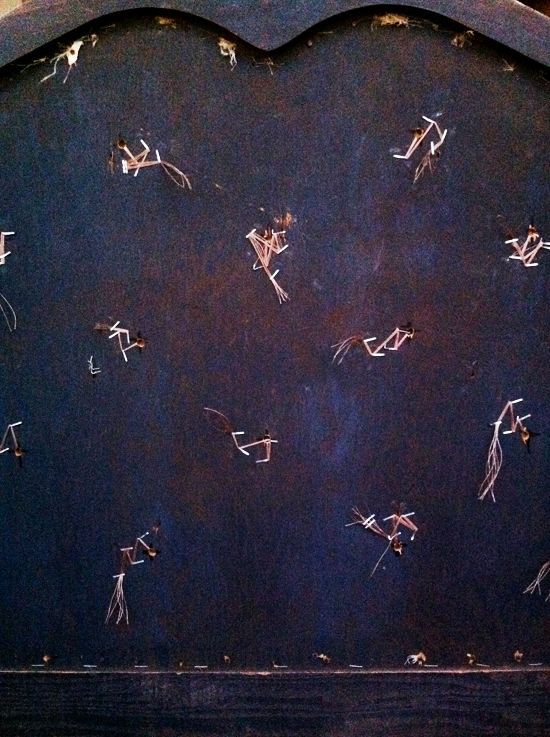

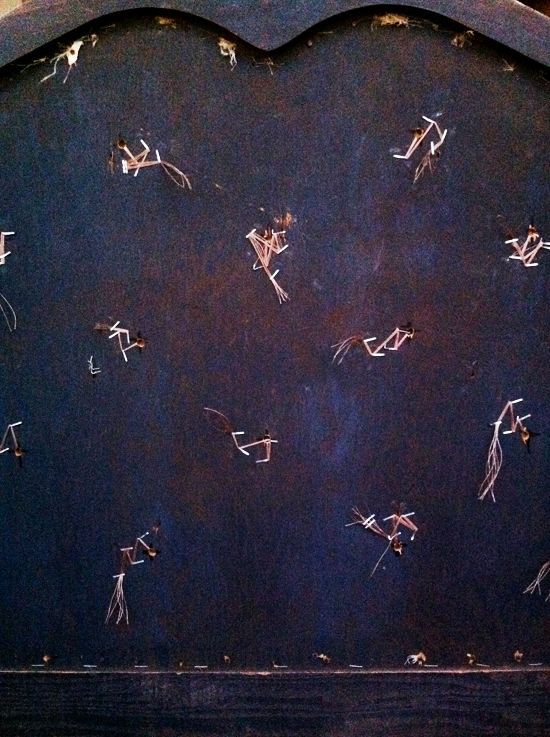

Once all the tufts are done, the back of your frame looks like this:

Almost there!

10) Next I trimmed away all the extra fabric and batting. Try to get as close to the staples as possible.

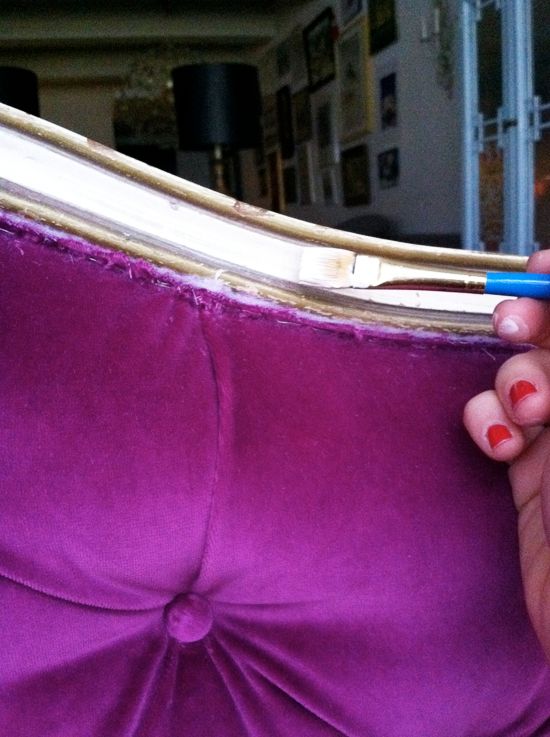

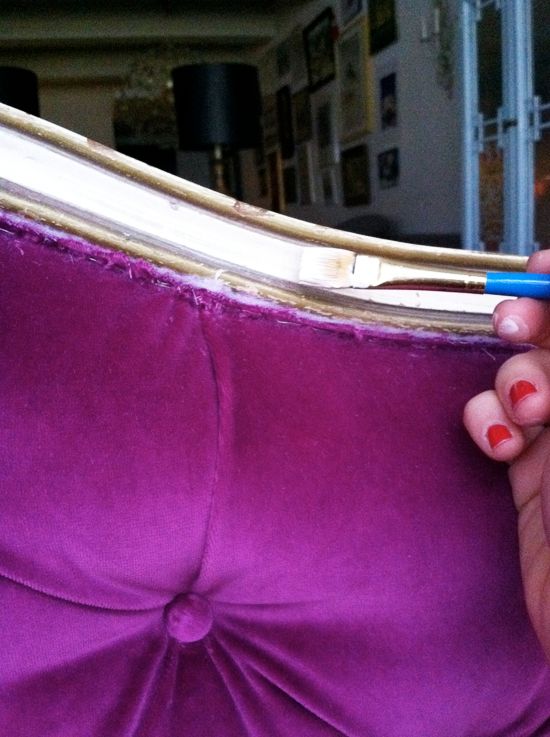

11. I decided I wanted to lightly touch up the frame. I always love the look of a crusty old frame with bright and clean new upholstery! But this frame was looking more dingy, less patina-ed, so I brushed on a little bit of white glaze and some of my favorite Ralph Lauren paint in Parlor Gold. Just a little bit of each though, so the frame still looked old.

All ready for the last step: trimming!

I used these steps to make matching piping out of the same velvet. I think the cording I used was 1/4". Nice and thick so it fills in the gap between the foam and the frame with all the staples and the fabric/batting mess.

I just used my favorite glue, Magnatac, to glue the piping in place. Use a generous amount, but be careful not to drip. It's really hard to get this glue off velvet especially.

7) With your helper pushing the button as far in as possible, pull the threads in back very tight and staple them down on to the frame. Pull the threads in the opposite direction and staple in again. Repeat a couple times and tap in the staples with a hammer to make sure the staples are flush and in there tight.

8) Here's the most important thing I can share with you here: Work in rows. Start with the middle button and work your way out in the row. Then start the next row in the middle again and work your way out.

Once you finish your first row and are ready to start the next row, play with your fabric and start making folds in a diamond shape. It's surprising how easily the fabric naturally folds into the diamond shape. The goal is for the surface of the upholstery to be smooth and as tight as possible. For a professional look, you want all the extra fabric to go in the folds.

Keep working away, going row by row, starting from the center and working out.

Once all the tufts are done, the back of your frame looks like this:

9) Staple around the perimeter of the headboard between the foam and the frame.

Another important part: Keep in mind that all interior folds should be in the diagonal/diamond shape. All the extra fabric around the perimeter of the headboard should go into vertical or horizontal straight line folds. Try to keep everything tight and smooth.

Another important part: Keep in mind that all interior folds should be in the diagonal/diamond shape. All the extra fabric around the perimeter of the headboard should go into vertical or horizontal straight line folds. Try to keep everything tight and smooth.

Almost there!

10) Next I trimmed away all the extra fabric and batting. Try to get as close to the staples as possible.

11. I decided I wanted to lightly touch up the frame. I always love the look of a crusty old frame with bright and clean new upholstery! But this frame was looking more dingy, less patina-ed, so I brushed on a little bit of white glaze and some of my favorite Ralph Lauren paint in Parlor Gold. Just a little bit of each though, so the frame still looked old.

All ready for the last step: trimming!

I used these steps to make matching piping out of the same velvet. I think the cording I used was 1/4". Nice and thick so it fills in the gap between the foam and the frame with all the staples and the fabric/batting mess.

I just used my favorite glue, Magnatac, to glue the piping in place. Use a generous amount, but be careful not to drip. It's really hard to get this glue off velvet especially.

All done! I know I always say this, but this project was so fast and easy. I started the project last night just after dinner time and was done after the Republican debate and two Walking Dead episodes. Not too bad!

I was so glad to be able to reuse those old headboards to get the exact look I wanted for my girls bedroom! I love the shape and it makes me so happy to have these special pieces in my home rather than a pair of more expensive and generic headboards from a place like Target or Urban Outfitters.